Near dry Edm

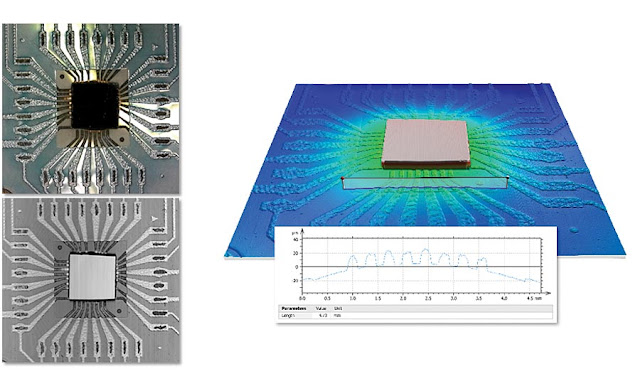

Team members : Ganesh Mokate 45 Gaurav Mane 42 Rehan Sayyed 65 Prathamesh Borude 09 Rohan Thorve 57 Introduction The electric discharge machining treatment is widely used for the production of complex profiles, electrically conductive material, high temperature resistance and high strength. Due to its wide application in industry, and so on, it has become the most popular process setting for conventional machining processes such as turning, milling, drilling, etc. Despite its many advantages, so the process tolerates a number of limitations, such as low material removal rate (MRR) and has a high consumption rate (TWR), as well as weak surface integrity, and in some cases. In the past, several attempts have been made to overcome these limitations associated with the growth of??? techniques, such as rotating the electrode by ultrasonic vibration and suspending powder in a dielectric liquid. Although these methods have a great research perspective, in practice they are used on...